Introduction

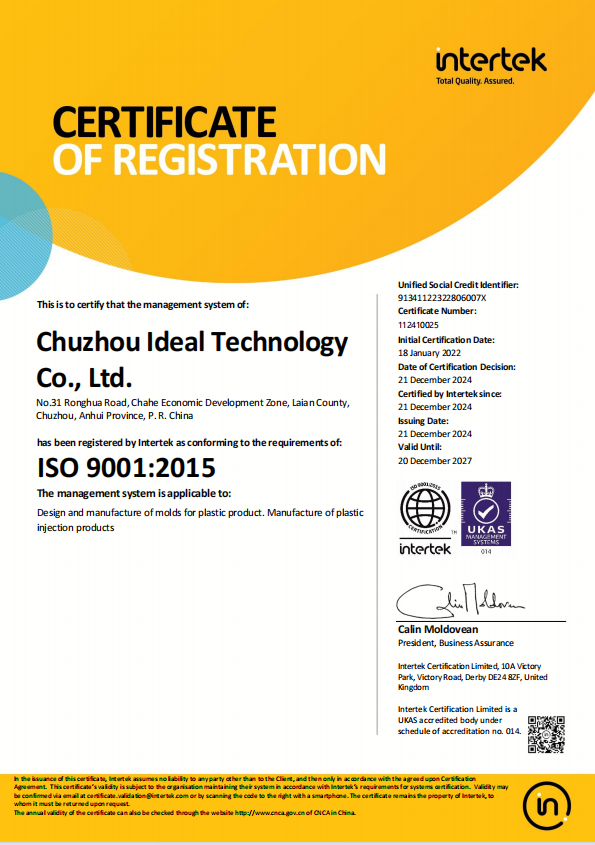

In the world of mold manufacturing, precision is everything. Whether you are producing automotive parts, medical devices, or consumer goods, even the smallest deviation in measurements can result in defective products. That’s why investing in high-quality measuring equipment is essential for ensuring consistency, accuracy, and efficiency. In this article, we’ll discuss the importance of measuring equipment in the mold manufacturing process and how it contributes to higher quality and reduced costs.

The Role of Measuring Equipment in mold Manufacturing

Measuring equipment is used to verify and monitor the dimensions and tolerances of molds and components throughout the production process. Accurate measurements are vital to ensure that molds produce parts that fit perfectly and perform as expected. High-precision measuring tools can detect even the smallest defects or inconsistencies, preventing faulty products from reaching the market.

Key Benefits of Using Advanced Measuring Equipment

- Ensuring Tight Tolerances: Accurate measurements ensure that parts meet the required specifications, even in industries with strict tolerances, such as aerospace and medical manufacturing.

- Improved Quality Control: Advanced measuring tools help manufacturers detect and correct issues early in the production process, reducing waste and rework.

- Enhanced Efficiency: By reducing the time spent on manual measurements and inspections, automated measuring systems increase the overall efficiency of the manufacturing process.

- Cost Savings: By identifying defects early, measuring equipment helps prevent costly production errors and minimizes material waste.

Conclusion

To stay competitive in the North American market, manufacturers must prioritize precision and consistency in their molding processes. Ideal Mold’s measuring equipment offers the accuracy and reliability needed to meet industry standards and deliver high-quality products. With the right measuring tools, businesses can enhance their production processes and reduce costs while maintaining excellent quality.