Introduction

Injection molding is one of the most widely used processes in manufacturing, especially in industries like automotive, medical devices, and consumer products. However, to stay ahead in today’s competitive market, manufacturers need injection molding machines that offer not only high-quality results but also enhanced efficiency and reliability. In this blog post, we’ll explore the benefits of modern injection molding machines and why investing in the right machinery is crucial for success in North America.

What is Injection Molding and How Does It Work?

Injection molding is a process where molten material is injected into a mold cavity, cooled, and then ejected to form solid parts. This technique is ideal for producing large quantities of parts with complex shapes and intricate designs. It is highly efficient, cost-effective, and versatile.

Why Invest in High-Performance Injection Molding Machines?

- Cost Reduction: Modern injection molding machines optimize material usage, reduce cycle times, and lower energy consumption.

- Customization and Flexibility: These machines offer greater flexibility, allowing manufacturers to produce a wide variety of parts to meet the specific needs of different industries.

- High Consistency and Accuracy: With advanced control systems, modern injection molding machines can consistently produce parts with tight tolerances and high-quality finishes.

- Sustainability: Newer machines are designed with energy efficiency in mind, helping manufacturers reduce their carbon footprint and adhere to environmental regulations.

Conclusion

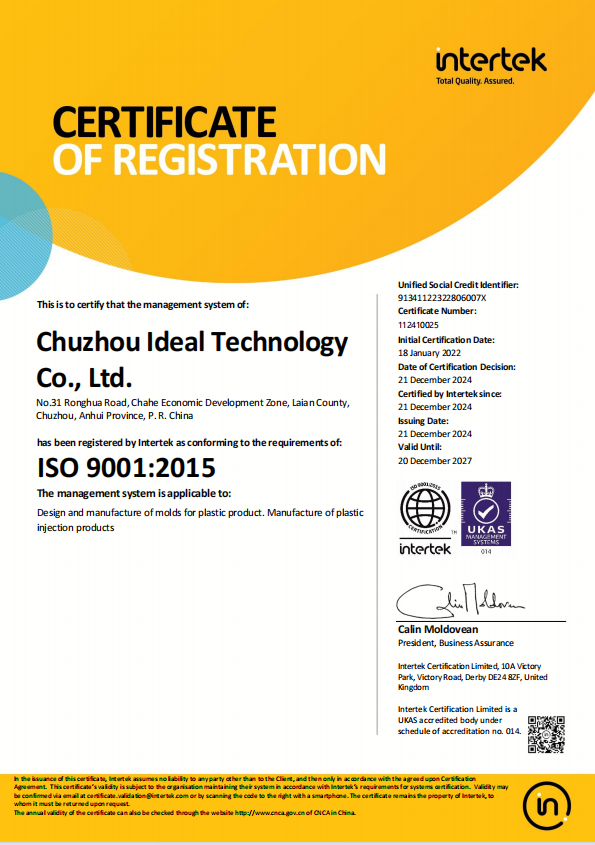

Investing in state-of-the-art injection molding machines can provide North American manufacturers with the ability to increase production efficiency, reduce costs, and maintain high-quality standards. Ideal Mold’s injection molding machines are engineered for maximum performance, helping businesses stay competitive in a rapidly changing market.