Introduction

The North American manufacturing landscape is constantly evolving, with a growing demand for precision, speed, and efficiency in production. To meet these challenges, businesses in sectors such as automotive, medical, and consumer goods must invest in cutting-edge mold processing equipment. In this article, we explore the importance of high-precision mold processing and how the right equipment can help manufacturers stay competitive.

Understanding the Need for Precision

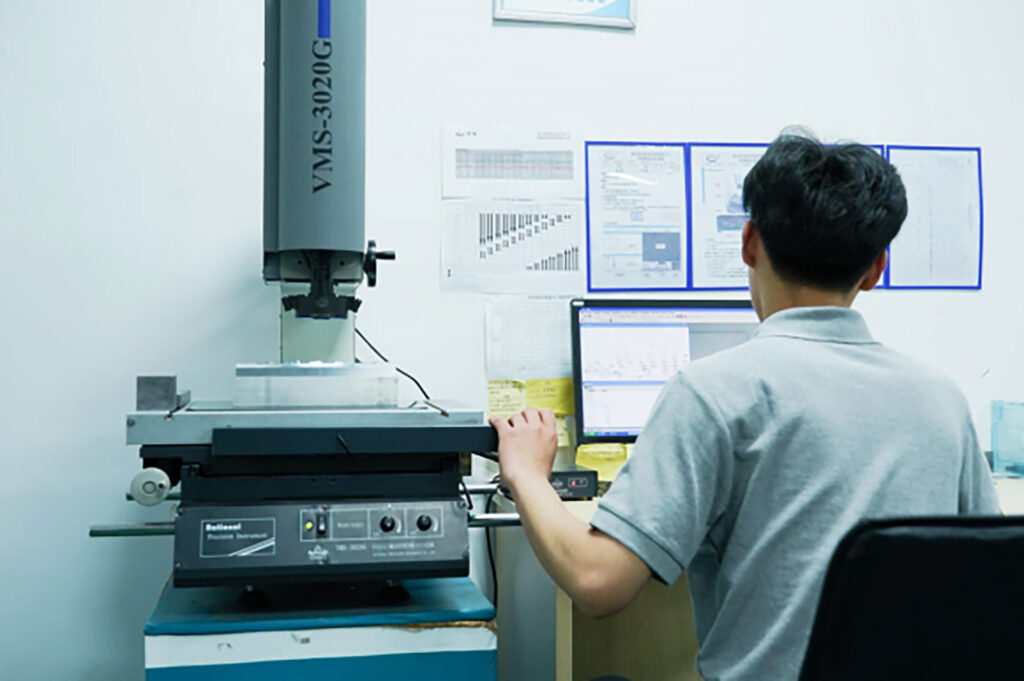

Precision is the cornerstone of successful molding. Even the smallest error in the molding process can lead to defective products, costly reworks, and delays. North American manufacturers need mold processing equipment that guarantees high accuracy, consistency, and speed to ensure optimal performance in high-volume production.

Benefits of High-Precision mold Processing Equipment

- Enhanced Quality Control: High-precision equipment minimizes human error, delivering products that meet stringent quality standards.

- Cost Efficiency: By reducing waste and rework, precision equipment helps cut costs in the long term.

- Improved Productivity: Faster cycle times and greater accuracy mean that manufacturers can meet tighter deadlines and increase output.

Conclusion

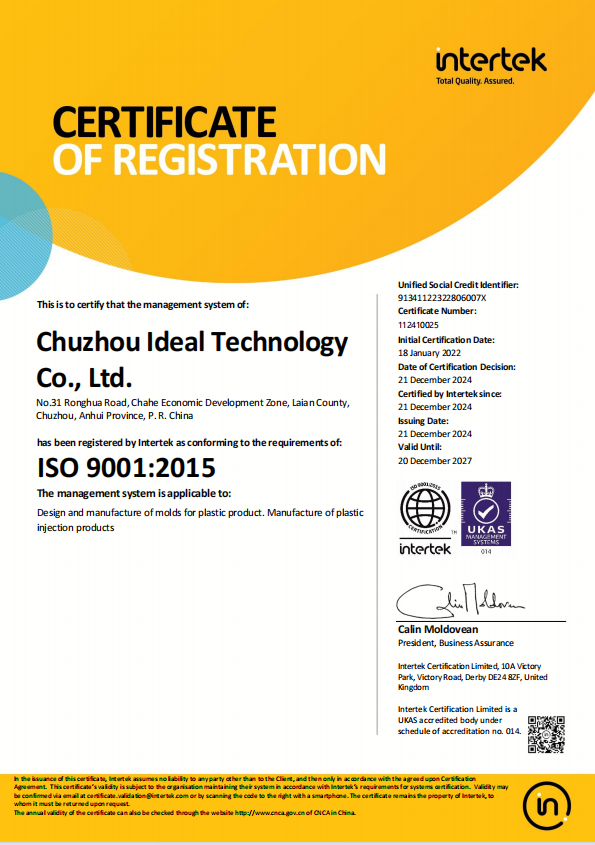

To remain competitive in the North American market, businesses must invest in advanced mold processing technology that delivers both precision and efficiency. Ideal Mold offers a wide range of mold processing equipment designed to meet these needs, ensuring that manufacturers can produce high-quality products at scale.